Using Bentley’s iTwin IoT Sets Foundation for Ongoing Intelligent Infrastructure Monitoring on Innovative Bridge Pilot Project

Virtual Model, Data, and Analytics in One Product

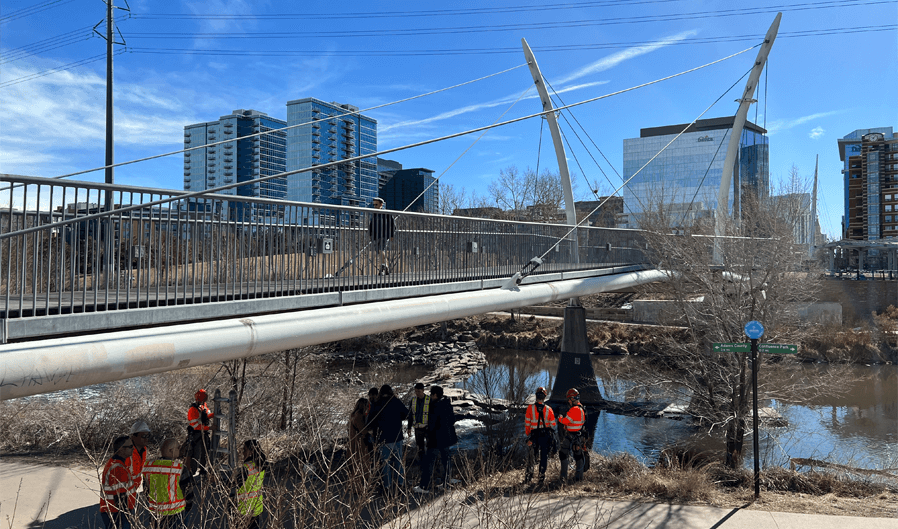

A unique pedestrian bridge connecting Denver’s booming Highland neighborhood to the downtown area is the perfect test site for a Stantec pilot project that’s advancing the next generation of Infrastructure Internet of Things (IoT) monitoring.

“This bridge moves a little more than it was designed to, it gets a lot more foot traffic than I think was ever expected,” said John Barone, infrastructure technology lead at Stantec. “There are no issues, but we wanted to find out more. And we don’t know a lot about how bridges move until we put sensors on them.”

He approached the City and County of Denver, with whom Stantec has a long working relationship, to use the bridge, which opened in 2006, as the test site for the cutting-edge project. “Structural health monitoring has been around for a while,” Barone said. “We’re going to the next level and creating a digital twin, which is a virtual, 3D representation of the actual asset.”

Fast facts

- The Highland Bridge is nicknamed the “Elephant Tusk Bridge” for its unique design’s curving columns.

- Wireless sensors have been installed on the bridge, providing real-time data to Bentley’s iTwin, which provides a virtual, 3-D representation of it.

- Stantec wanted to test a digital twin software to provide a proof-of-concept for other jurisdictions.

Dynamic Data for Intelligent Infrastructure

In February, the team met in Denver with city staff to kick off the project. They installed approximately 15 low-cost wireless sensors along the length of the Highland Bridge, affixing them with epoxy that will last for many years. The sensors measure movement correlating to structural health, sending readings to iTwin IoT in real time.

“iTwin IoT allows us to set thresholds for vibration and movement,” Barone said. “Any time it exceeds those thresholds, the city gets notified and [they] can address the issue immediately.”

Along with providing a cost-effective way of increasing risk management and safety through real-time alerts, iTwin IoT offers a central, shared single source of truth for all data and analytics about the bridge. Besides sensor data, Stantec gains insights from historical records and images, future maintenance schedules, and weather or temperature readings. All information about the structure from a variety of sources is contained within iTwin IoT.

iTwin IoT is a significant advancement over the status quo for many municipal and state infrastructure and transportation departments, as they often store data in disparate locations, on hard drives or other external sources, and without shared access.

“We are tying it together to give our client access to all the information about this bridge in one place,” Barone said. “But then we want to go to the next step.”

“iTwin IoT allows us to set thresholds for vibration and movement. Any time it exceeds those thresholds, the city gets notified and [they] can address the issue immediately.”

-John Barone, Infrastructure Technology lead, Stantec

Unlocking the Digital Twin Toolkit

iTwin IoT is more than just a data repository. In the virtual environment, users can zoom around a model of the bridge to see a sensor’s location and access it to see what is happening at that data point.

Along with creating 3D models based on design plans, iTwin IoT also features the ability to layer in other modes. Stantec flew a drone around the Highland Bridge to capture high-resolution images from which a reality capture model will be built by using iTwin Capture, allowing engineers to compare design plans to the bridge’s actual condition. High-resolution images of cracks or other potential problems can be brought into the model for monitoring.

A potential next step is putting cameras on the bridge to better understand the factors affecting bridge movements, such as high traffic or heavy loads. The overall goal is to develop a real-time picture of what’s happening to drive safety and more efficient, proactive maintenance.

“What does it cost to do emergency repairs in the middle of the night because of a problem?” Barone said. “Preventative maintenance is so much cheaper than reactive. Ultimately, we are looking at using AI and machine learning to do predictive analytics.”

The Future of Digital Twin Technology

Eventually, the sensor data that is being collected on Highland Bridge may provide insights that apply to other bridges. “This project will start Denver on a journey to gathering a lot of data about their bridges,” Barone said. “As they install more sensors, they will become much more useful because they will have a comparison dataset that we don’t have today because it’s brand new.”

Stantec is using iTwin IoT to set the stage for the city to have all its infrastructure monitored and managed in a digital twin, including utilities such as water and sewage, roadways, and data on drainage and slope stabilization.

“That’s our ultimate goal; that’s the future,” Barone said. “This project is just the first step to get us there. Right now, the industry is in an amazing shift,” Barone said. “It’s such an exciting time to be involved in digital delivery projects and operational excellence solutions.”

ROI

- The real-time sensor data will improve the city’s safety and asset management.

- Data from the sensors provides longer-term insights into bridge movement for predictive maintenance.

- The iTwin IoT platform sets the foundation for ongoing intelligent infrastructure monitoring.